America’s Oil Boom Can Not Happen Without Groundwater

Risks are substantial in New Mexico’s Permian Basin

A drilling rig explores for oil in southeast New Mexico’s Permian Basin, one of the most productive sources of shale oil in the U.S. More than 80 rigs now operate in the area outside Carlsbad. Photo © Keith Schneider / Circle of Blue

By Keith Schneider, Circle of Blue

CARLSBAD, NM — Deep beneath the desert that surrounds this oil boomtown is a fossil fuel bounty of staggering riches reachable only by penetrating vulnerable beds of porous limestone and soluble salt at considerable environmental and public risk.

Carlsbad is the industrial hub of southeast New Mexico’s mammoth Permian Basin oil field that yields more than 540,000 barrels a day — 30 percent more than a year ago and a record in a region that has been exploring for oil and gas since the late 1920s. The field’s surging production has pushed New Mexico to the #3 spot, behind only Texas and North Dakota, as one of the nation’s most prolific oil producers.

The city looks the part. At night the steel superstructures of 85 drilling rigs, lit like carnival rides, fill the horizon. The long white flames of flared gas are a constellation of ground-level stars adorning the dark.

Just how hot the oil play has become was illustrated last September when developers paid $130.9 million for the right to tap the layers of carbon-rich shale below 15,491 acres of federal land near Carlsbad — the highest price ever for an oil and gas lease sale in New Mexico. Months earlier Exxon Mobil paid $5.6 billion for 250,000 acres of New Mexico desert already leased for energy exploration.

But unleashing billions of barrels of oil locked in beds of shale 10,000 feet deep is only possible if the oil industry — and state and federal regulators — safely manage production challenges involving the region’s other primary resource: water.

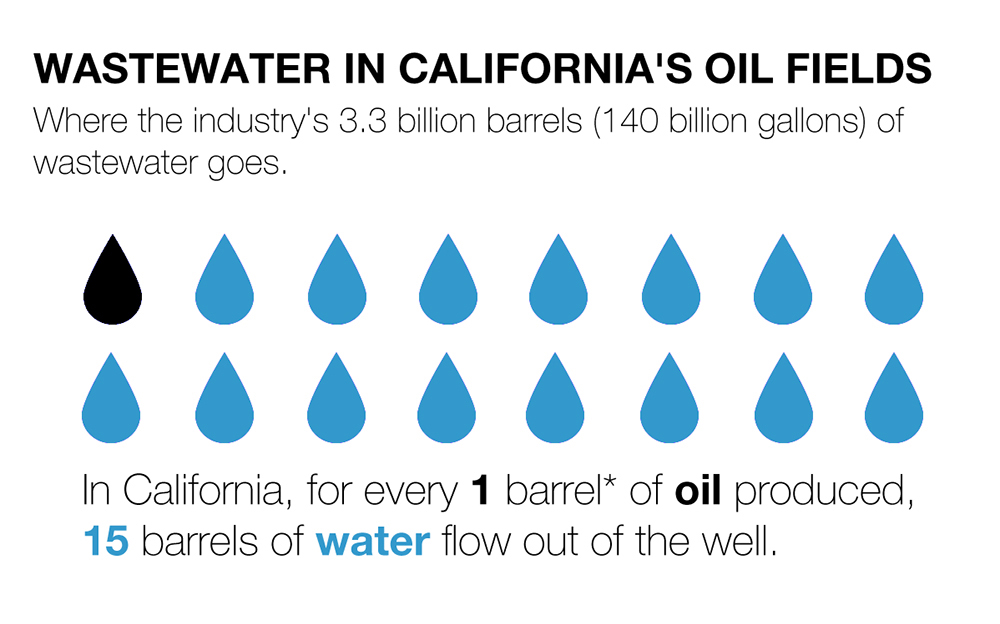

Drilling, fracking, and extracting crude oil and natural gas from shale requires prodigious volumes of water in the world-class energy fields in New Mexico, Texas, and five other Great Plains states that now supply almost 70 percent of the country’s 10.1 million-barrel-a-day production, the most ever. But because of distinctive geology and unusual hydrological conditions, nowhere are the ties between oil and water more demanding than in New Mexico’s Permian Basin.

“Conditions here are unique,” said Ed Martin, assistant commissioner in the New Mexico Land Office, which manages nearly 2 million acres of state land in three southeast counties for energy production. “The volumes of water the industry uses are so prolific. The disposal problems are more pronounced. The potential for something to go wrong is higher.”

Regulators and oil industry executives need look no further than the southern edge of this city of 55,000 people, about half of them itinerant oilfield workers, for compelling evidence of just how hazardous the ties between oil production and water management can be. After years of indecision, city, county, and state authorities just agreed to spend $40 million and hire an engineering firm to prevent a gigantic sinkhole from opening in salt beds just a few miles from Carlsbad’s central business district.

For 30 years, until it was shut down in 2008, an oilfield services company poured millions of gallons of fresh water into the ground to dissolve a thick salt layer and produce brine for the specialized oil and gas drilling operations needed here. Brine is essential to drilling oil and gas wells through the region’s pervasive salt beds, because fresh water melts salt and causes structural instability in oil and gas wells.

Engineers estimate that if the surface of the so-called “Carlsbad brine well” collapses, the crater — 700 feet long and 450 feet deep — would swallow several existing businesses and one of the city’s busiest highway intersections. The calamity, according to the most recent estimate, could cost $1 billion in business losses and environmental damage.

That danger is real. A decade ago two similarly big sinkholes opened in the unpopulated desert 22 miles and 29 miles northeast of Carlsbad, destroying brine-producing companies that operated the same way. No one was injured, but the giant holes remain, like craters of the moon.

State regulators, oil industry executives, and local authorities assert that the slow-motion events at the brine well are an unintended consequence of oilfield production practices outlawed a decade ago. There’s little sense of alarm in Carlsbad, though, or among state agencies.

Outside New Mexico, activists aware of the situation express considerably more panic. “It’s like they put the risk aside, roll the dice, and hope for the best,” said Taylor McKinnon, public lands campaigner for the Center for Biological Diversity in the group’s office in Flagstaff, Arizona. “I find it shocking. What if it happens? What if a drilling operation triggers a collapse? It would be a disaster and would be a total scramble for every public official that oversees that industry.”

“It shows,” McKinnon added, “how much deference the oil industry gets in that community and the state agencies.“

“It’s a bit of a race against time,” said George Veni, the director of the National Cave and Karst Research Institute, a geological sciences group based in Carlsbad, who co-chaired the city’s technical advisory committee. “The latest engineering report said that the collapse is going to happen. Not if, but when. It could happen anytime, but 2021 is more likely.”

Regardless of the varying levels of distress, the potential for collapse illustrates just how vulnerable southeast New Mexico is to mistakes in oil and gas production. “It’s not a panic situation,” said Veni. “But a lot can go wrong if extreme caution is not displayed.”

A Swift Current Underground

Not only do thick beds of soluble salt lie above New Mexico’s oil and gas-producing shale, so do layers of porous limestone that hold huge reserves of water. The region is so geologically exceptional that in 1923 the United States established an underground national park, Carlsbad Caverns, to make nearly 47,000 acres of magnificent limestone caves permanently available for human exploration and bat habitat.

Studies that released harmless dye into the limestone by the Bureau of Land Management, a unit of the Interior Department that leases roughly 3 million acres of public land here, show that oil and toxic materials from a big spill or leak could move quickly and contaminate thousands of acres of aquifers used for drinking water.

Every day some 115 million gallons of wastewater from oilfield operations moves across the desert of southeast New Mexico’s Permian Basin. About half is recycled and reused to drill and frack new oil wells. The other half is injected into the ground at wastewater disposal sites like this one near Carlsbad. Photo © Keith Schneider / Circle of Blue

State regulators insist that rigorous rules and sufficient numbers of inspectors safeguard water and land from the more than 600 wells being drilled annually in southeast New Mexico and from the roughly 26,000 already in production. “There is no evidence of groundwater contamination” associated with fracking operations, according to Beth Wojahn, communications director for the Energy, Minerals and Natural Resources Department, which oversees energy development.

The BLM, for its part, requires wells drilled into porous limestone across its domain to be secured in three layers of casing to prevent leaks.

Still, the potential for significant damage is ever-present. The state Land Office counts 570 old and abandoned oil and gas wells in southeast New Mexico that have not been properly closed and plugged. According to the agency, none are leaking.

In 2017, the Oil Conservation Division documented nearly 800 incidences involving surface spills or leaks of oil or production fluids in Eddy and Lea counties, the two primary energy-producing counties. Some 10,000 barrels of oil and 75,000 barrels of fluid were spilled, according to state records. But just a single fine of $30,000 was levied by the state in 2017, according to online records.

Millions of Gallons Down the Well

Episodic spills and enormous volumes of water are two distinguishing characteristics of the contemporary American oil booms that sweep into small cities closest to the country’s largest oil fields.

There are others. Rooms at Carlsbad’s budget hotels cost $250 a night and are difficult to find. Long lines develop at McDonald’s for breakfast in the morning, and at convenience stores at dusk for beer, cigarettes, and salty snacks. “Man camps” of recreational vehicles and fifth-wheel trailers occupy open fields. The Walmart parking lot is full of shoppers by day and people sleeping in their vehicles at night. Tanker truck traffic is so heavy, and moving so fast, that two-lane highways have evolved into killing zones. Last year on U.S Highway 285, the main north-south corridor, 115 crashes caused 57 injuries and killed 7 people, according to the Eddy County sheriff’s department.

Oil, of course, is the resource that drives the boom. At more than $60 a barrel and climbing, the recent price increase has caused a stampede of drilling in the two-state Permian Basin, most of which lies in Texas and now accounts for more than 2.2 million barrels of oil a day, or more than one in five barrels produced in the nation.

Water is the other vital resource for keeping the cost of gasoline (in constant dollars) at the roughly same price it was in the mid-1970s. Everywhere oil and natural gas are extracted from deep shale — in a cluster of states along the upper Ohio River and on the Great Plains from North Dakota to Texas — developers are managing huge volumes of water.

The Gregory family of southeast New Mexico developed the nation’s first pipeline transport network to supply water for drilling and fracking deep oil-saturated shale. Pipelines eliminated thousands of truck trips between water sources and drilling sites. In 2017, the family sold the company to Select Energy Services, a Houston oilfield company. Photo © Keith Schneider / Circle of Blue

During the drilling stage, millions of gallons of “produced water” contained in shale are drained from the formation and brought to the surface. Thousands of gallons of water are needed to mix drilling muds. Some 3,400 gallons of water are needed, according to state figures, to frack every horizontal foot of a production well. Such “laterals,” as they are called, often are 10,000 feet long and can consume nearly 34 million gallons. About half of that “frack water,” contaminated with chemicals and toxic constituents from the shale, is brought back to the surface.

Every stage of the water-intensive production process has stirred public concern in the country’s fracked energy fields. In Pennsylvania a number of drinking water wells near fracked natural gas wells became contaminated, prompting protests and lawsuits. In North Dakota, traffic deaths caused by water truck collisions spiked, and rates of violent crime linked to drivers climbed. In Ohio and Oklahoma, injecting fracking wastewater into disposal wells caused earthquakes.

In southeast New Mexico, roughly 300,000 barrels (12.6 million gallons) of water, most of it transported by pipe, is used to frack oil wells daily. Some 2.5 million barrels of wastewater and produced water are generated daily, according to state figures, and transported by truck and pipeline. About half of the produced water is treated and recycled for reuse in drilling operations in the growing number of treatment plants in the region. The rest is pumped down some 721 wastewater injection wells that the state regulates in the region.

‘They Want the Bad Water’

There are big fortunes to be made producing New Mexico’s oil and natural gas. There are smaller fortunes to be made in supplying and treating water.

Earlier in this century, when fracking first gained hold in the Permian, Larry and Scott Gregory saw an opportunity to sell water from wells on their big ranch northwest of Carlsbad to nearby drilling companies. The brothers, raised in New Mexico in the 1950s and 1960s, had already earned industrial legitimacy by designing and manufacturing shipping casks for nuclear waste. They used those same engineering and entrepreneurial skills to form a new division of Gregory Rockhouse Ranch, designing and operating the country’s first network of wells, pipes, and pumps to supply water to a major oilfield.

The water supply system now encompasses over 100 wells, 300 pumps, and over 1,000 miles of flexible polyethylene pipe capable of supplying more than 200,000 barrels of water daily, a supply system that can be quickly picked up and moved as demand requires. The sources for most of the water are aquifers filled with brine of varying salinity and not fit for drinking or agriculture. The company also buys a small amount of treated wastewater from Carlsbad’s municipal sewage treatment plant.

The oil industry is steadily shifting its practices to eliminate fresh water from its operations, said Larry Gregory, the co-founder. “Anything close to potable water, they won’t buy from us. They want the bad water. They have an image they are trying to protect.”

Donny Gregory (l) is the director of operations for Select Energy Services in southeast New Mexico. He stands with Christopher Lewis, lead field person, during a morning project to repair a water line gashed by a truck. Photo © Keith Schneider / Circle of Blue

A year ago the brothers sold the operation to Select Energy Services, a big oilfield services company in Houston. The Carlsbad division employs over 100 people, operates out of an industrial yard near the city’s center, and is managed by younger members of the Gregory family. Water customers from Select Energy and other suppliers pay 85 cents to over $1 for every barrel of water they buy, and include the biggest oil companies in the country, including Exxon Mobil, Conoco, and Chevron.

“The company evolved as the demand grew,” said Gregory. “We provided a service that made the industry safer. We take 60,000 trucks a month off the road by moving water with our pipes.”

But while commanding about half the drilling water market, the Gregorys purposefully avoided handling the much bigger market for treatment and recycling. Capital requirements are intense, as increasing competition for fresh water in a region with scarce moisture pushes the industry to invest in treatment infrastructure for recycling water.

“Chevron has nearly eliminated the use of fresh water for well completions, relying, instead, on low-quality brackish water and recycled produced water,” said Veronica Flores-Paniagua, an external affairs advisor for Chevron North America, in an email message. “Recycling produced water has the additional benefit of reducing the amount of water we need to dispose once a well has been completed.”

The state now counts 27 water treatment and recycling plants in southeast New Mexico. About half are on state land and capable of treating nearly 400 million gallons of water at a time. Six more are either planned or under construction. The newest is a $12 million plant being built in the desert north of Carlsbad by Occidental Petroleum. It spans 80 acres and includes 8 big ponds to settle, treat, and recycle water.

“New Mexico’s Permian basin has a 50-year supply of oil,” said Aubrey Dunn, the New Mexico Land Commissioner. “We need to be careful to make sure we have a 50-year supply of fresh water. The key to the long-term ability of the basin to survive is to treat and recycle produced water and wastewater. Water is the limiting factor in this whole development.”

Circle of Blue’s senior editor and chief correspondent based in Traverse City, Michigan. He has reported on the contest for energy, food, and water in the era of climate change from six continents. Contact

Keith Schneider

Leave a Reply

Want to join the discussion?Feel free to contribute!