Q&A: Subir Bhattacharjee on the Geopolitics of Oil and Alberta’s Tar Sands

Subir Bhattacharjee — a professor of mechanical engineering at the University of Alberta and one of Canada’s top water quality experts — tells Circle of Blue about the water cycle of the tar sands.

With astonishing speed, and considerable risk to water supplies and wild lands, the global energy industry is massing to significantly reduce imports and push North America higher on the list of the world’s top oil-producing regions. Canada’s tar sands — which are located beneath a Florida-sized stretch of northern Alberta — are a big reason why energy economists are convinced that such a huge change in the sources and geopolitics of oil is possible. Energy companies are converting bitumen, the asphalt-like compound embedded in the tar sands, into 1.5 million barrels of oil a day, three-quarters of which is exported to the U.S as fuel or raw synthetic petroleum.

But converting bitumen to fuel involves enormous open-pit or steam-injecting mining operations that are reshaping a forested landscape, sharply increasing pollution, and consuming huge quantities of fresh water. The toll on the environment, especially on the region’s water supply, is awakening vigorous public opposition and prompting the major companies to undertake new fields of research to reduce water contamination and consumption.

In March, J. Carl Ganter, Circle of Blue’s director, interviewed Subir Bhattacharjee, a professor of mechanical engineering at the University of Alberta. One of Canada’s top water quality experts, Bhattacharjee is developing new technology and practices to prevent tar sands development from polluting northern Alberta’s freshwater reserves.

You need to clean it up, so it can be fed into a boiler that will make it steam. This is a very energy-intensive process, especially when you have water-treatment technologies that are conventional and require you to bring the temperature of the water down to very low values, to make it amenable to treatment by these technologies. Then you have to heat this water back to steam. That also involves a lot of energy. This a very interesting facet of the global challenge when you are producing energy: how much water you are consuming. And how much energy you have to spend to clean that water back up.

In the context of oil sands production, this is a very challenging issue. You are using a very clean-burning hydrocarbon like natural gas to produce oil. There should be some questions asked about the use of one type of fuel to produce another type of fuel. Now again, I think one of the rationales is that the fuel that we produce is a transportation fuel, and its value should be differently assessed compared to natural gas, which is not traditionally a transportation fuel.

Mining uses surface water, and it is quite water intensive. The total water requirement to produce a barrel of bitumen would be approximately 17 to 19 barrels, according to most estimates. A lot of this water is held in tailings ponds and is recycled back to the process. So, what you have is the net water intake. The net freshwater intake for these plants is about 1.8 to 2.4 barrels for each barrel of bitumen produced. If you start out a new bitumen operation, a lot of water is needed. As a plant gets normalized and starts operating in its regular cycle. it uses less and less fresh water. But that number, according to most companies, is not less than 1.8 to approximately two barrels of water per barrel of bitumen.

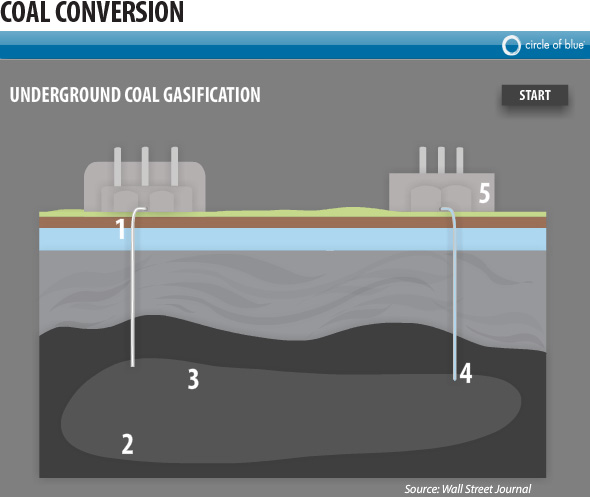

The steam-assisted gravity drainage is a slightly different story. To produce a barrel of bitumen, you need a total of three barrels of water to be boiled to produce steam. The process will not make economic sense, if the steam-to-oil ratio goes anywhere above five barrels of water per barrel of oil. Given that steam oil ratio of three-to-one, with a 90 percent recycle regimen, the amount of water required inside the operations is never more than .3 to .4 barrels per barrel of bitumen — so, this is a much lower water footprint than the mining. There is also less water to dispose of.

In mining bitumen, you do not dispose any water: you store all the water, because the policy is zero liquid discharge. That’s the reason we have about 750 million cubic meters (198 billion gallons) of tailings ponds, which is growing in Alberta. It’s a legacy that we have, because we always had a policy that there was no need to treat the water.

My short answer is that I don’t have a very clear idea. Globally, we have a fixed amount of total water in various geographical regions. In certain places you may have sufficient water to produce oil, but the water is coming from a very saline groundwater formation. To clean it up — to reduce the salt content to a level where it is more amenable to processing oil — is a huge energy consumer. Or you are in a water-stressed region that has enough water for producing oil, but does not have enough to grow crops: so how would you allocate that water? Would you transport it to first produce the crop and send it back to produce oil? Or can someone use water that has been contaminated by oil, treat it, and actually use it for agriculture?

These questions will be big driving issues in terms of water being the choke point, the decisive factor that will decide the price of oil. It’s not yet there, but, most likely, the price of water will dictate what the price of oil is.

So, if you take that argument the other way, you basically say that the cost of water and the cost of energy to produce a barrel of oil has a strong correlation with the current price of oil. So, what you are seeing is that the price of oil reflects the price of the other commodities that have been used to produce that oil. By the way, I don’t see hydrocarbon resources depleted anytime soon. We’ll find new types of hydrocarbon resources.

There will be small paradigm shifts over the next decade, which relate to getting distributed water sources for people who are in different locations. [For example,] coastal communities around the world will have to start looking at saline water to get their drinking water, [since] the cost of transporting water from inland over a long distance to coastal communities is starting to make less and less sense.

J. Carl Ganter is co-founder and director of Circle of Blue, the internationally recognized center for original frontline reporting, research, and analysis on resource issues with a focus on the intersection between water, food, and energy.

Leave a Reply

Want to join the discussion?Feel free to contribute!