Singapore uses treated wastewater to expand its drinking water supply.

By Brett Walton

Circle of Blue

Recycled treated wastewater, which Singapore has branded “NEWater”, is providing 30 percent of the Southeast Asian island city-state’s total demand for fresh water.

The small, densely populated island enjoys heavy rainfall, but lacks sufficient watersheds and natural rivers from which to draw water. Because space to store water is so tight, the city of five million residents has always relied for its drinking water on unconventional sources—including imports—and has transformed two-thirds of its landmass into storm and water catchments.

Until this year, imports from neighboring Malaysia accounted for 40 percent of the nation’s 300-million gallon daily demand for fresh water. For political and economic reasons, however, the government decided not to renew the import contracts, which were signed in 1961 and expire in 2011 and 2061.

When imports end, Singapore’s three freshwater sources will be local—rainfall in catchments, desalination, and NEWater.

NEWater is Singapore’s own brand of reclaimed water and is essentially wastewater purified by two rounds of treatment. Initially used for industrial purposes only, a small portion of NEWater is now returned to reservoirs, where it blends with rainwater before entering the standard drinking water treatment and distribution system.

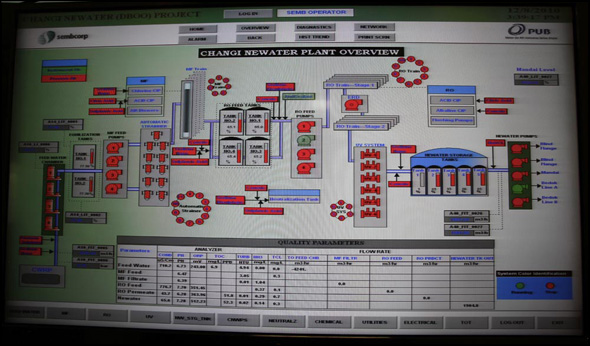

To make potable water out of what goes down the drain and toilet, Singapore’s NEWater recycling plants take water from standard treatment facilities and then use an additional three-step purification process: micro-filtration, reverse osmosis, and ultraviolet treatment. The end product meets drinking water standards set by the World Health Organization, the U.S. Environmental Protection Agency and Singapore’s own national agency.

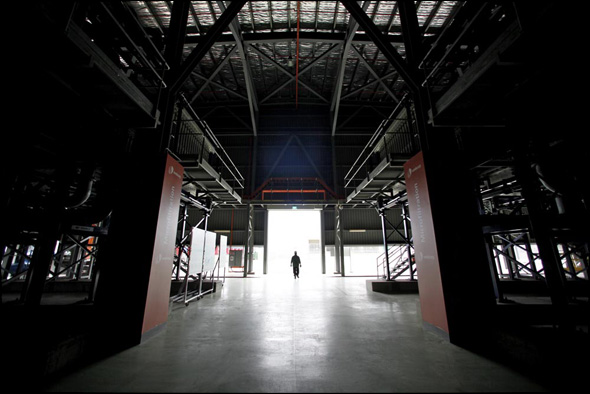

In May 2010, Singapore opened its fifth and largest NEWater plant, which has the capacity to recycle up to 176 million gallons per day.

NEWater is distributed by Singapore’s water utility through the tap, and it is also distributed in bottles at the NEWater visitor center and at community promotional events.

Note: This article has been corrected since first publication to reflect that NEWater is not sold in stores.

Brett Walton is a Seattle-based reporter for Circle of Blue. Contact Brett Walton

Last month, Circle of Blue director J. Carl Ganter toured the NEWater facility and brought back images of the daily operations at one of the world’s largest water recycling systems. Reach him at jcarl@circleofblue.org.

Brett writes about agriculture, energy, infrastructure, and the politics and economics of water in the United States. He also writes the Federal Water Tap, Circle of Blue’s weekly digest of U.S. government water news. He is the winner of two Society of Environmental Journalists reporting awards, one of the top honors in American environmental journalism: first place for explanatory reporting for a series on septic system pollution in the United States(2016) and third place for beat reporting in a small market (2014). He received the Sierra Club’s Distinguished Service Award in 2018. Brett lives in Seattle, where he hikes the mountains and bakes pies. Contact Brett Walton