Resurrecting an Old Desalination Technology to Test Desert Agriculture

At a U.S. desalination research facility this month, a 2,500-year-old technology will be put to the test. The company in charge of the project hopes to increase productivity, reduce the energy needed to purify water and maybe even make desert agriculture viable.

Brett Walton

Circle of Blue

Back when Athens was the center of the world, Aristotle wrote in Meteorologica, his examination of the natural sciences, that the processes of evaporation and condensation, when applied to salt water, turned the foul liquid into sweet. “This I know by experiment,” he wrote.

Since then, those same processes have been incorporated in the solar still, a device that uses sunlight to produce freshwater. For centuries, the water-purifying apparatus has been used to supply drinking water to small communities around the world.

But now, crafty engineers both in the U.S. and abroad who recognize global constraints on land, food production and water resources are laying out bigger plans. Besides producing fresh drinking water, they envision using evaporation and condensation to resurrect the solar greenhouse, an idea that, according to Hill Kemp — the CEO of the desalination start-up Suns River — has been “tossed in the boneyard of technology” but could turn tracts of coastal desert into productive land.

Last September, his company received one of nine grants for water purification research handed out by the U.S. Bureau of Reclamation. This month, Suns River will begin testing one of its solar stills at the bureau’s Brackish Groundwater National Desalination Research Facility in Alamogordo, N.M.

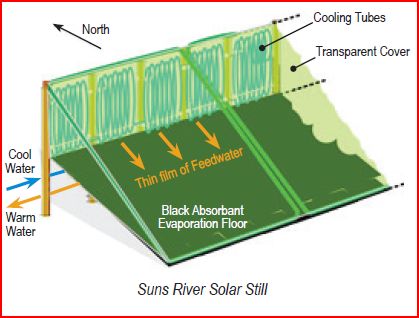

Solar stills remove most contaminants from water — all salts, heavy metals, bacteria and microbes — by passing a thin film of feed water across a dark surface tilted toward the sun. As the water evaporates, it condenses into droplets on a clear plate above the black floor and rolls downward to a collection trough. A carbon filter then removes any remaining organic compounds.

A still’s productivity increases with the amount of incoming solar energy, or insolation. With the solar conditions in the U.S. Southwest, an average still could produce about 0.8 liters (0.2 gallons) per sun hour per square meter, according to a demonstration project funded by the U.S. Environmental Protection Agency (EPA). Larger surface areas generate higher output.

The stills have been a blessing in regions that don’t have easy access to freshwater. The EPA-funded project tested hundreds of solar stills in the unincorporated communities, or colonias, along the U.S.-Mexico border.

The colonias often are not connected to a public water supply system and are located in areas without clean groundwater. They rely on bottled water or supplies that are trucked in — expensive options compared to the stills. Surveys taken as part of the project found widespread satisfaction with the units.

Vipin Gupta, a Reno, Nev.-based physicist with Sandia National Laboratories who was involved with the colonias project, told Circle of Blue that the decentralized nature of the solar still makes it an attractive technology for communities in similar environmental and economic circumstances.

But for the stills to be more widely adopted, Gupta said, designers need to find more durable and affordable materials. “The device has to withstand sunlight, water, salt and wide temperature differences,” he said. “It’s a demanding environment for any material. That’s the biggest technological challenge today.”

From Water to Food

A former chemical engineer and Texas state legislator, Kemp decided to focus on the solar still while looking for solutions to climate change. After reading books and articles describing the technology, he set out to improve the standard still’s efficiency.

He has made enough progress to receive federal grant money, but his proposal also came along at the right time.

The Bureau of Reclamation considers the technical merit of all projects, said Kevin Price, the desalination research program coordinator, but some years certain attributes are placed higher in the pecking order. During the last funding cycle, the bureau looked for projects that incorporated renewable energy.

“We want to see something innovative with renewables because we have not seen a lot of proposals coming in,” Price said. “We’ve focused on small rural systems recently.”

In January, Kemp was awarded a U.S. patent for his design, which, he said, increases both the evaporation rate and the condensation rate. For at least the next four months those claims will be tested in New Mexico, but the still could potentially produce three to five times the water per square meter that a typical still device does, at comparable cost.

According to Kemp, improving the still’s efficiency is a first step in a longer journey toward a new agriculture in which evaporation and condensation are harnessed to turn coastal deserts into suitable sites for greenhouses.

Several organizations working in the world’s driest regions have similar goals. In Qatar and Jordan, the leaders of the Sahara Forest Project plan to grow crops in desert greenhouses and turn sandy swathes green — but by using salt water instead of scarce freshwater supplies.

Taking advantage of the desert heat and a seaside location, cold ocean water would be circulated through the greenhouses, creating a humid environment and nurturing the crops through condensation. The facilities would generate power from concentrated solar plants located on-site and cooled by the easily accessible seawater. But most of the energy produced would go toward reverse osmosis desalination units that would irrigate forests to store carbon.

Though the project has the support of two of the world’s largest fertilizer and nutrient companies — Yara and Qafco — and the Norwegian government, it is still years away from a commercial roll out.

The project’s chief executive Joakim Hauge told Circle of Blue in an email that there are several scientific and technical studies underway, as well as materials testing and computer modeling. Once those are completed, a demonstration project will begin, possibly in 2012, on 0.2 square kilometers (20 hectares) of land near Aqaba on Jordan’s Red Sea coast.

The largest commercial project of this sort is already running in Australia. Sundrop Farms, in the state of South Australia, grows high-value crops such as tomatoes. The farm began life using seawater greenhouses, but has since developed solar power technology that desalinates water for the crops and provides most of the energy needed for operations.

Last year the farm produced a crop with a commercial value of AU$450,000 (US$481,770) at its 2,000 square meter pilot project. The company plans to expand by constructing a 0.2 square kilometer (20 hectare) greenhouse.

Note: This article has been updated with information from Sundrop Farms about its crop production and technology.

Brett writes about agriculture, energy, infrastructure, and the politics and economics of water in the United States. He also writes the Federal Water Tap, Circle of Blue’s weekly digest of U.S. government water news. He is the winner of two Society of Environmental Journalists reporting awards, one of the top honors in American environmental journalism: first place for explanatory reporting for a series on septic system pollution in the United States(2016) and third place for beat reporting in a small market (2014). He received the Sierra Club’s Distinguished Service Award in 2018. Brett lives in Seattle, where he hikes the mountains and bakes pies. Contact Brett Walton

You have done a good job of touching on most of the relevant technologies in this field… please make it a regular feature, blog, or whatever. Missing is Carl Hodges’ (Seawater Foundation) work in Mexico and Eritrea with Halophytes and actually farming in seawater with dense Mangrove plantings and Salicornia and others.

Kudos